When investing in new equipment, why not select the machine with all the bells and whistles?

When investing in new equipment, why not select the machine with all the bells and whistles?

That was our thinking when we decided to purchase three new PUMA 2100SY II Y-Axis Horizontal Turning Centers to replace five of our older lathes.

These powerhouse machines increase our capacity for high-volume, large-diameter parts; improve accuracy and reliability; and enable us to perform complex, high-speed milling, while still maintaining the clearance and spindle RPM to be efficient on small parts.

Large Bar Capacity

We’ve always been able to turn large-diameter parts in lower volumes. Now, we can bar feed parts up to 2.625” in diameter, easily fulfilling high-volume production machining orders of up to 10,000 parts.

Need parts with an ever bigger diameter? No problem. For high enough volumes, we can use the robot cells we build in-house to automate production for turned parts up to 10” in diameter on the same machines.

Need small-diameter parts that aren’t a good fit for swiss machines? We’ve got you covered. The PUMA 2100SY is also excellent for running small parts down to 0.5” in diameter. The direct-drive spindle reaches 6,000 RPM and the extra rigidity is a huge benefit in tougher materials, making the machine incredibly efficient for fulfilling high-volume production orders of small parts.

Efficient Scaling

We know from experience that having multiple of the same exact machine gives us incredible flexibility when it comes to scaling parts for high-volume production machining. With three identical PUMA 2100SY II lathes, we have greater scheduling flexibility and can easily replicate the setup to multiple machines to increase production volume.

Tight-Tolerance Mill Features

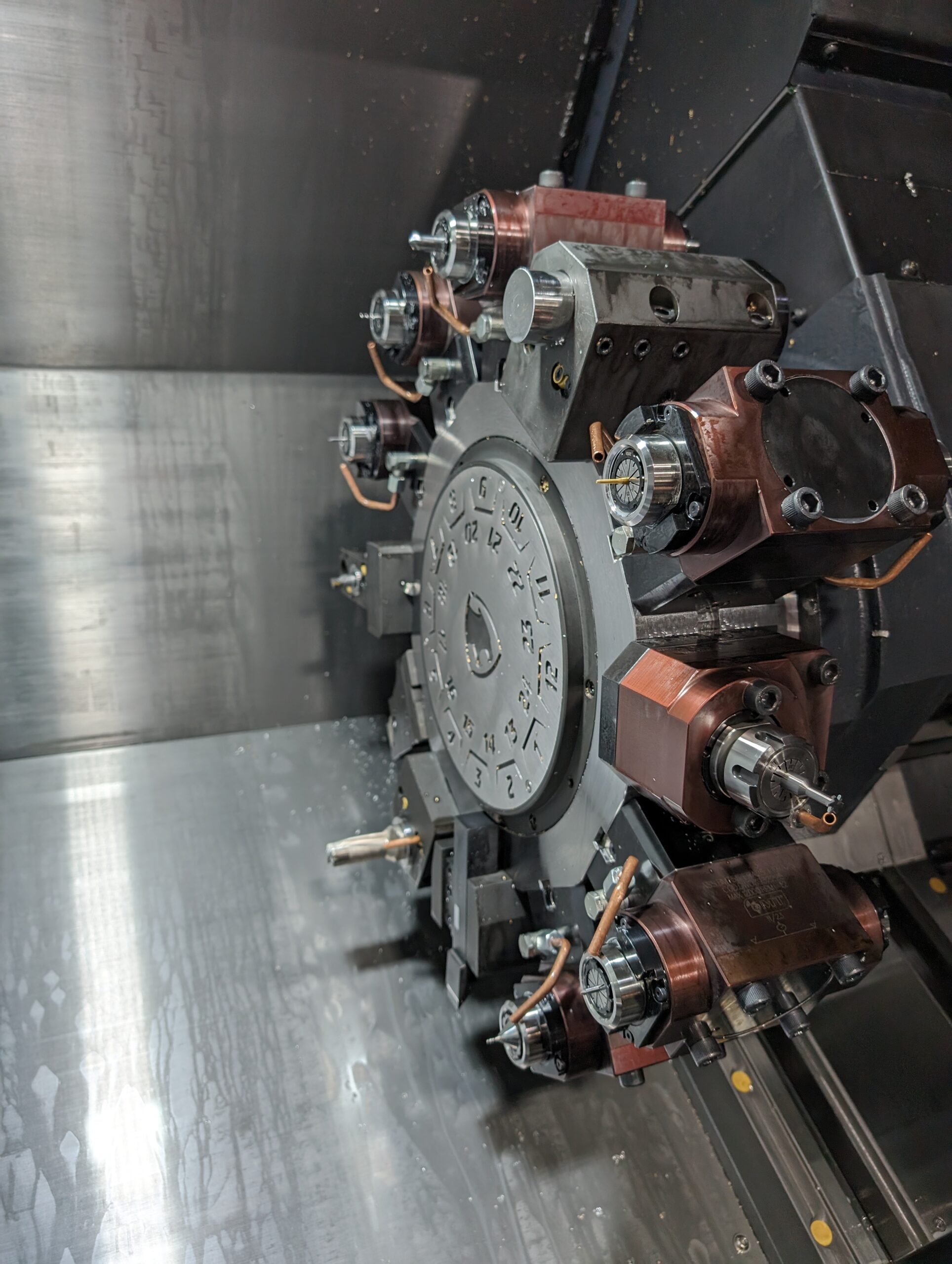

Not your typical 2-axis lathe, the PUMA 2100SY can produce milled features thanks to high-speed BMT65P live tooling and Y-axis capabilities. Most live tooling maxes out at 5,000 RPM, but with our configuration, we can mill at speeds up to 10,000 RPM, allowing us to cut intricate features more efficiently than is typically possible with live tooling on a lathe. BMT65P tooling is also larger than the live tooling on many lathes and helps us machine parts with tighter tolerances and better finishes. We just finished an order where around 2/3 of the tools were used for milling processes. We can’t show the parts, but check out that tooling!

One-Operation Machining

It’s no secret that we’re proponents of “done in one” machining. Equipped with live tooling and a sub spindle, the PUMA 2100SY can complete an entire part in one operation, guaranteeing superior accuracy and repeatability.

Extra Weight and Rigidity

The PUMA 2100SY weighs more than twice as much as each machine we replaced. The resulting extra rigidity minimizes vibration, allowing us to machine tougher materials while maintaining a better tool life and achieving better part finishes. Typically, heavy machines are known for being slow—but not the PUMA 21000SY. This machine provides the best of both worlds: high weight and high speed.

Want to put our new turning centers to the test for your next high-volume production machining order? Request a quote to get started!