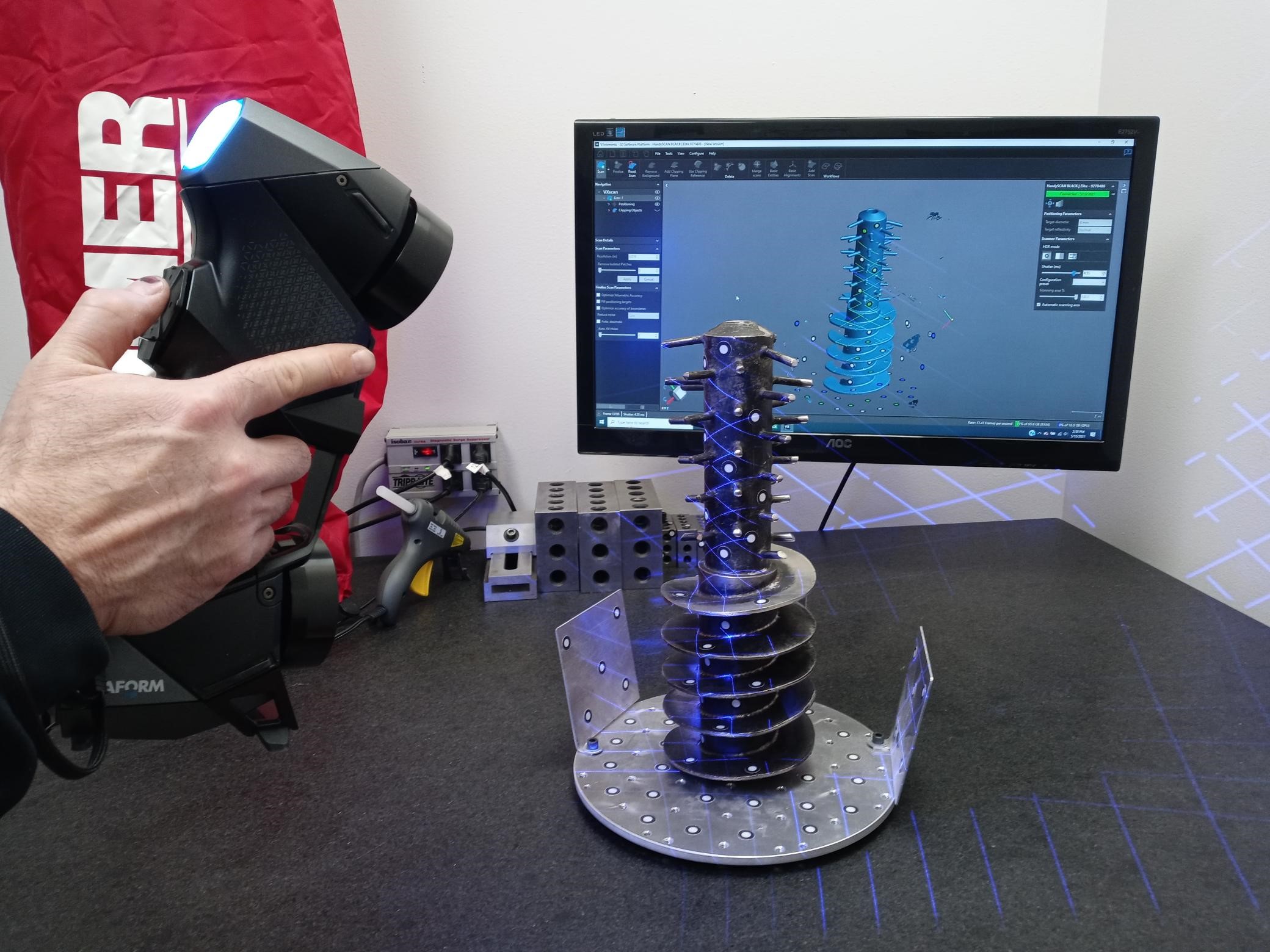

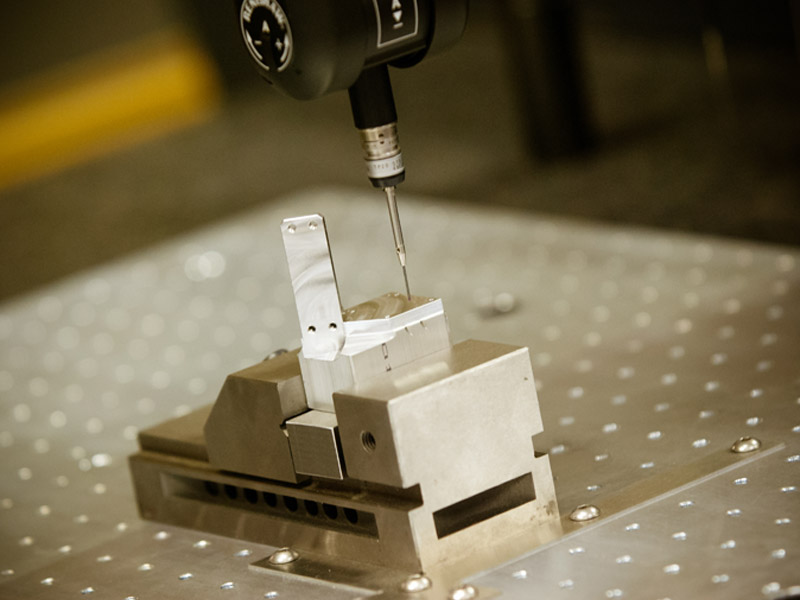

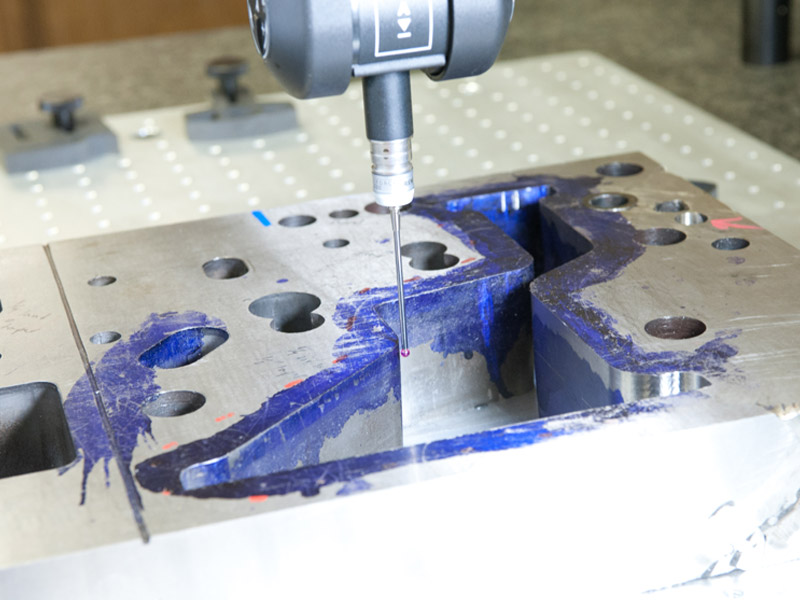

If you don’t have prints for your parts, don’t worry about it. We have invested in a portable CMM and a high-resolution laser scanner for repair and reverse engineering. These tools allow us to measure and reproduce any part from a sample, even if it is broken. Measuring parts at our facility with all our tools is ideal. It is also possible for us to set up at your place to measure parts on the equipment it runs on. We have over 20 years of reverse engineering experience for both repair and reproduction of complex parts. Our extensive experience covers reverse engineering of die components, machinery, conveyor systems, automation, and packaging system components.

To complete the reverse engineering process, we have several CAD programs that we use depending on your preferences and the type of part we are measuring. For parts measured with our CMM that don’t have freeform surfaces, we generally use a combination of DezignWorks and SolidWorks. This provides a parametric solid model that can be exported to almost any CAD software. For extremely complex shapes with truly freeform geometry, we use our laser scanner. Geomagic software makes working with large point clouds and freeform surfaces easy and fast. It also allows us to create parametric solid model files that can be exported and used with most CAD and CAM software.

Whatever method we use, we will end up with a solid model and print of your part that we keep on record in case you ever need another one made. We aren’t stingy with our prints either since you pay for us to make them. We can provide prints and solid model files in any format you need. All of this technology feeds into our manufacturing system. We use solid models to program our machines and to inspect the final parts. Our goal is to make sure you get a perfect part the first time.