Our Wire EDM

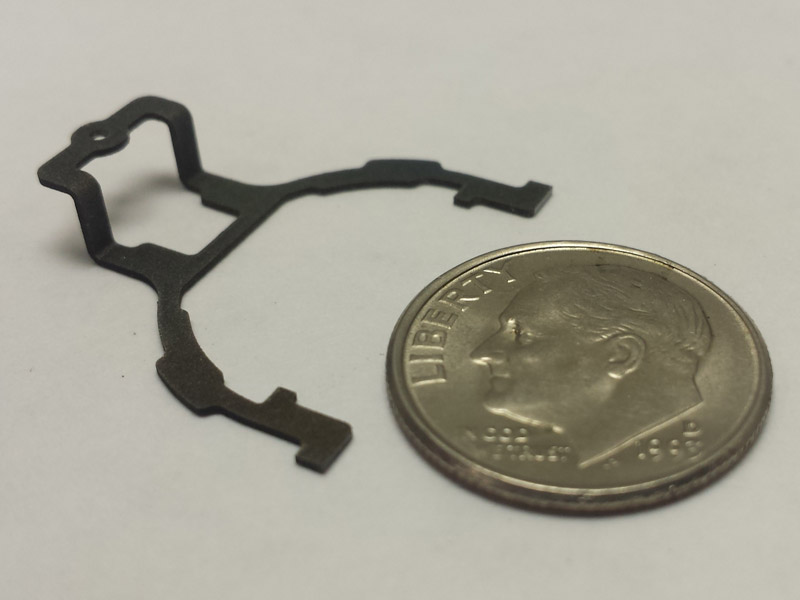

We have a Makino DUO64 wire EDM. It has an automatic wire threader, and is capable of full 4 axis cutting. It can cut parts up to 15.7”(400mm) thick x 26.0”(660mm) wide x 35.8”(910mm) long. We use a .010”(.25mm) wire, which allows us to cut fine details.

Our Experience

Unlike many EDM shops, we have experience cutting a wide variety of parts from an equally wide variety of material. While we have cut a lot of die components, we have spent an equal or greater amount of time cutting unique parts from difficult materials. We have experience cutting irregular shapes that require custom fixtures. For example, we have cut custom keys and splines in large hubs and gears. We have even cut specimens from railroad track, requiring special fixtures to cut at specific angles. Cutting complex geometry is also something that we do on a regular basis. We cut taper angles on many parts, and we also cut parts using full 4 axis. We use an advanced CAM program that makes any geometry simple and fast to program.

As far as material goes, we have cut just about anything that an EDM can cut. We have spent plenty of time cutting tool steel, mild steel, stainless steel, copper, brass, and aluminum. We have also cut various exotic alloys, as well as many custom engineered materials that are truly one-of-a-kind.

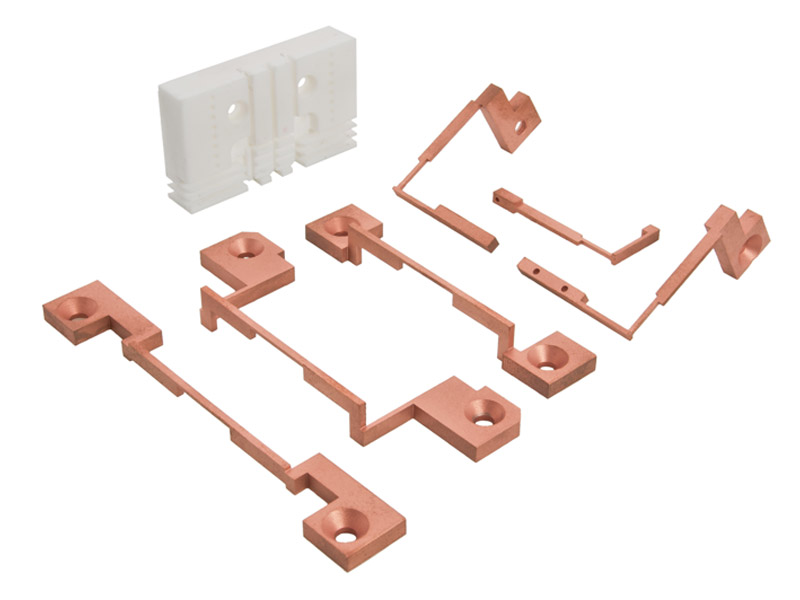

One thing that we do on a very regular basis, is use the EDM process to save time on complex parts. We make a lot of high precision parts with complex shapes from steel, copper, and aluminum. We have found that cutting the blanks with the EDM can often help reduce the time required for other operations. Aluminum and copper also cut extremely fast on the EDM (often 3-5 times faster than steel), which makes the process ideal for a wider variety of parts.

As with every other process, we document our jobs, by saving the programs, setup sheets, and digital pictures of our setups. This information is all linked to our MRP software along with any other operations that the parts require. The data is backed up on our network, as well as off site, and is easily accessible so we can reference old jobs to find useful information for new challenges.