There are certain scenarios when buyers and engineers may consider having their CNC machine shop provide assembly services. At Wagner Machine, assembly services fall under our secondary and support capabilities, meaning they are available to customers who partner with us for primary precision machining services.

Here’s a closer look at when it makes sense to ask us about assembly services and how you can benefit from them.

When to Ask a CNC Machine Shop about Assembly Services

If you’re contemplating outsourcing assembly services to a CNC machine shop, one of the main factors to consider is the percentage of components the shop manufactures for that assembly.

Suppose Wagner Machine is only making 10% of the components in your assembly. In that case, it probably doesn’t make sense to ship us 90% of the components. You’re better off building the assembly at your facility or outsourcing it to an assembly firm.

However, if we’re already manufacturing most of the components in your assembly or sub-assembly, you could benefit from having us assemble the components for you. For the right projects, the reduction in the number of individual parts you store and track in inventory along with reduced internal assembly may lead to noticeable overall cost and time savings.

How Customers Benefit from Our Assembly Services

The primary advantages of having a CNC machine shop assemble your components are to consolidate vendors, ensure consistency, and simplify purchasing, receiving, and inventory management.

As you know, any opportunity to reduce vendors and purchase orders makes buyers’ and engineers’ lives much easier. When you only have to coordinate with one CNC machine shop, the entire process is streamlined. More importantly, entrusting precision machining services and assembly services to the same shop ensures consistent quality, fit, and finishes.

Furthermore, we apply the same rigorous quality and inspection processes you can expect for precision machining services to assembly services. If you already have defined assembly procedures we are happy to follow them. If not, we clearly define the assembly process and identify any areas that could inhibit the fit and function of the assembly. If required, these key features are inspected and recorded just like part dimensions which can greatly reduce the amount of incoming inspection work required on your end.

Sample Assembly Project: Portable CAT Scanner

Wagner Machine has successfully completed a number of assembly projects over the years. Most of our projects have 10 or fewer components if stock hardware is excluded, but we also tackle much more complex assemblies.

One of our most memorable assembly projects was a portable CAT scanner. We leveraged in-house capabilities such as waterjet cutting, 5-axis machining, CNC turning, and more to create the individual components. Then, we built a full assembly, even performing some basic wiring to complete a mechanical frame onto which the customer would mount the final components: an X-ray source and detector that were worth several times the cost of the rest of the assembly.

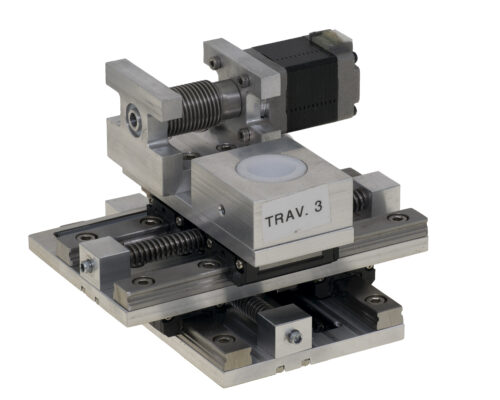

We’ve also completed some really cool sub-assemblies for drones, medical devices, and optical assemblies that require serial numbers, matched sets, custom packaging, and more.

Ask Us about Assembly Services

The Wagner team enjoys the challenge of building assemblies and is excited to take on more of these projects. If you’re requesting a quote for precision machining services and are interested in having us assemble the components, be sure to let us know!