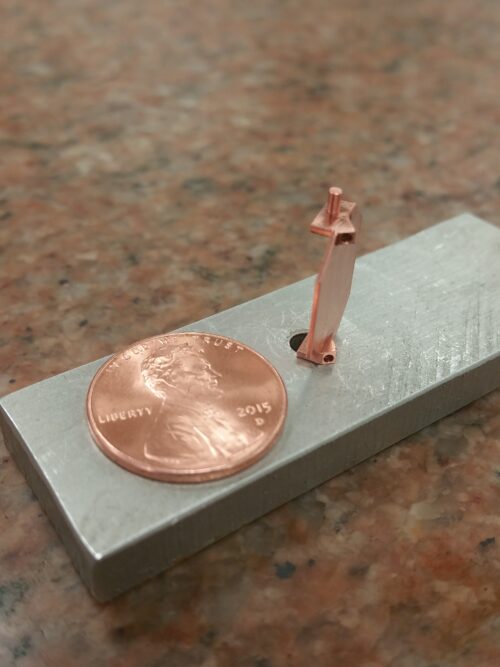

When it comes to machining, feature size can change the entire process. We call the smallest machining we perform “micro-machining,” but it isn’t simply about working on small parts. It’s about making incredibly small features, often smaller than a millimeter, and doing so with a level of precision that goes far beyond standard machining.

At Wagner Machine Company, we’ve built a reputation around our ability to create these intricate parts. But over the last few years, we’ve taken on more jobs with features so tiny they challenge even the seasoned team here at our precision machine shop.

Here’s what it takes to achieve high-quality parts using a micro-machining process, from the first cut to the final product.

How We Define Micro-Machining

At Wagner Machine, we define micro-machining based on feature size, not part size. It is common to see average size parts with multiple micro-machined features. Small or “micro” features create unique challenges: once you’re working with features or tools smaller than one millimeter or 0.039”, everything changes.

At Wagner Machine, we define micro-machining based on feature size, not part size. It is common to see average size parts with multiple micro-machined features. Small or “micro” features create unique challenges: once you’re working with features or tools smaller than one millimeter or 0.039”, everything changes.

At this scale, the everyday tools and processes most machinists rely on quickly turn into gray areas. Feeds and speeds, and length to diameter ratios still apply. The cutting process is theoretically the same, but the way we “dial it in” has to change. The features are so small that you can’t see what’s happening during a cut, you can’t hear when a tool is struggling, and you certainly can’t “eyeball” anything. Every step of the micro-machining process requires thoughtful planning and surgical-level precision, from machining to deburring to finishing/cleaning and beyond.

What We Consider During the Micro-Machining Process

In the world of micro-machining, everything starts with the right strategy. Machining process, tool selection, toolpath direction, order of operations, and workholding all influence whether we can make a part successfully and finish it well.

Let’s take toolpaths, for example. In standard machining, there’s often room to clean up small burrs with a secondary pass. But in micro-machining, that pass might not be possible. The edge break tolerance might be as small as 0.0005”, which won’t allow most tools to cut properly. Instead of forming a chip, the tool will often simply deform the metal and leave behind multiple burrs.

We program and analyze toolpaths down to the individual segment level to address specific issues, adjusting direction, feed rate, and RPM as needed to ensure the part has no burrs even without a conventional deburring pass. Autodesk PowerMill allows us to dial in every detail, and this level of control is essential to creating a consistent and repeatable micro-machining process.

And when you can’t see or hear what the tool is doing in real time? That’s where experience and data come in. Microscopic inspection tools, including Keyence optical systems, are used to evaluate machining results, and years of experience are used to troubleshoot issues one-thousandth of an inch at a time.

How We Deburr Delicate Micro Features

Once we’ve machined the parts, the next step is deburring, which removes any sharp edges or microscopic burrs from the machining process. When your entire feature may only be .010” wide, a typical .005” edge break doesn’t work. For micro machined features, you usually don’t want a measurable edge break so we have special processes to “soften” the edges.

Once we’ve machined the parts, the next step is deburring, which removes any sharp edges or microscopic burrs from the machining process. When your entire feature may only be .010” wide, a typical .005” edge break doesn’t work. For micro machined features, you usually don’t want a measurable edge break so we have special processes to “soften” the edges.

Some work is done manually under a microscope. This micro-deburring process might involve using fine tools, picks, or even toothbrushes to knock off any “fuzzy” edges. Low speed brush wheels are another option, but only under tightly controlled conditions. Brush speed, type, and contact time are all critical when a few extra seconds could completely remove an entire feature. Another method is non-abrasive tumbling. Since we are starting with almost no burrs in the first place, these processes are all designed to remove minimal amounts of material.

Finishing Considerations for Micro-Machined Parts

The last stage in our micro-machining process is finishing. While deburring focuses on edges and removing obvious FOD (foreign objects or debris), finishing is about smoothing surfaces, removing minor scuffs, thorough cleaning, and improving the overall aesthetic of the part.

One of our go-to finishing methods is micro-tumbling. We use stainless steel pins smaller than a millimeter to gently soften edges and create a uniform finish. There is no abrasive used in this process, which is critical in many micro-machining applications. It ensures a very consistent part finish from batch to batch and straddles the line between deburring and finishing.

We also use microblasting, which is exactly what it sounds like. This miniature version of sandblasting is so delicate that you can hold the parts in your bare hands or nitrile gloves for processing. Our team selects abrasive materials like ceramics, glass beads, or sodium bicarbonate based on the part requirements. Sodium bicarbonate (more commonly known as baking soda) is especially useful for sensitive aerospace or defense components, as it breaks down on contact, is water-soluble, and leaves no embedded residue. Another critical aspect of micro blasting is that all media is single-use, so there is no chance of cross-contamination.

As a final step, many parts require ultrasonic cleaning. Cleaning solutions vary based on customer and material requirements, but the end goal is a part with no FOD even on a microscopic level. Many parts require 100% visual inspection under magnification after this process.

Before we decide on the right finishing method, we’ll speak with the customer to determine which finishing and cleaning methods are appropriate to work with with plating, bonding, or assembly steps.

Why Experience Matters in Micro-Machining

In an optimal micro-machining process, simply having small tools is not enough. A manufacturer needs to understand how every detail affects the next step. You need a team that can anticipate challenges, refine the process, and maintain control at every stage.

At Wagner Machine, we invest in:

- Inspection systems that see what humans can’t

- Highly trained machinists and quality personnel who understand the big picture, from programming through inspection and finishing

- Unique machining, workholding, and deburring strategies that we customize for each part

Many of the parts we work on are one-of-a-kind challenges that call for custom setups and creative problem-solving. Many others have to be optimized for repeatable and consistent production manufacturing. Our team is constantly developing and refining processes to deliver the highest-quality parts possible, no matter how complex or delicate the features may be.

Whether you need micro lathe parts, micro mill parts, or high-volume production machining, Wagner is ready to help. Request a quote today to get started on your next project with our CNC machine shop!