Our Mill Department

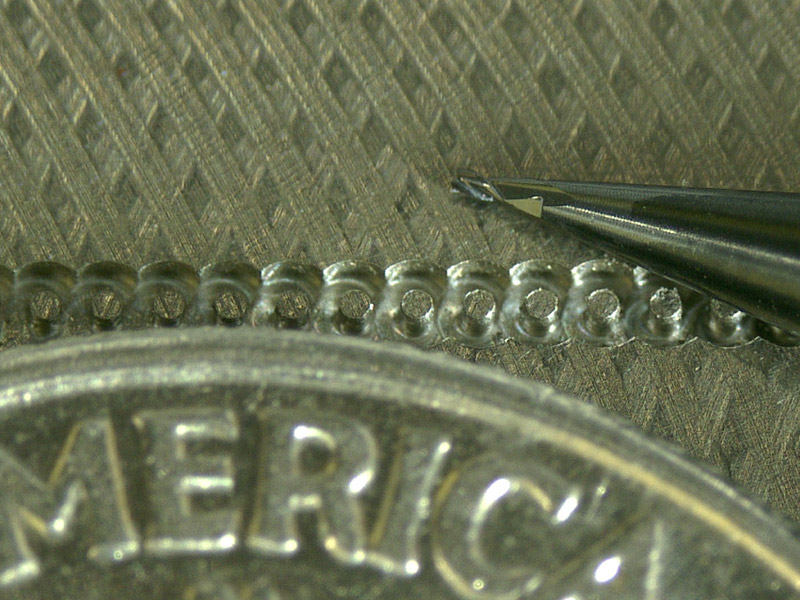

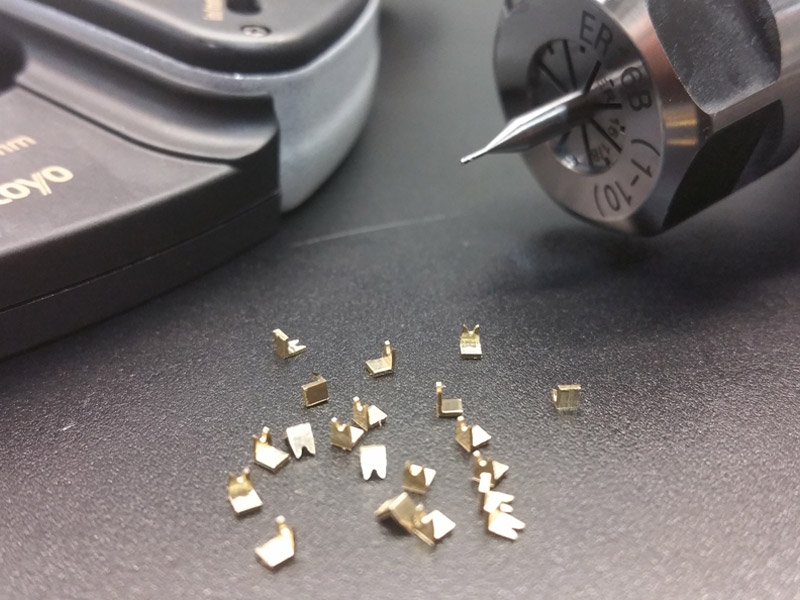

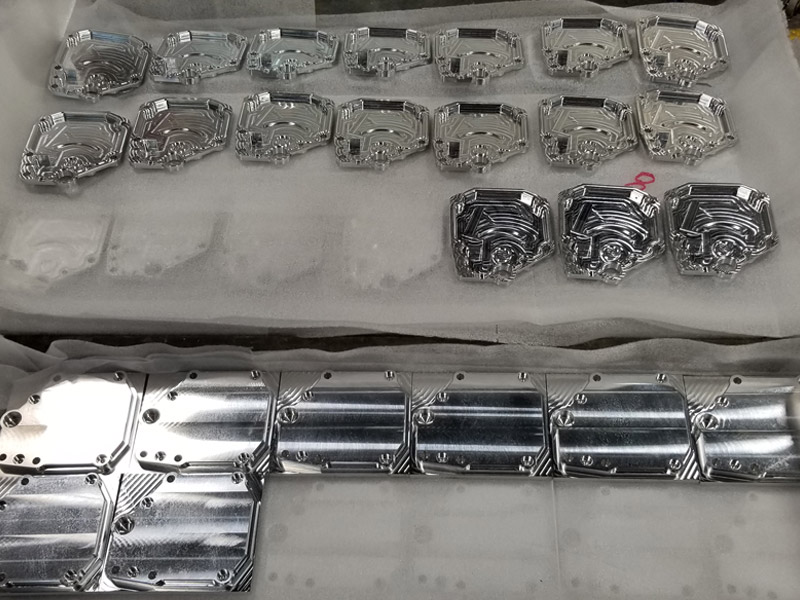

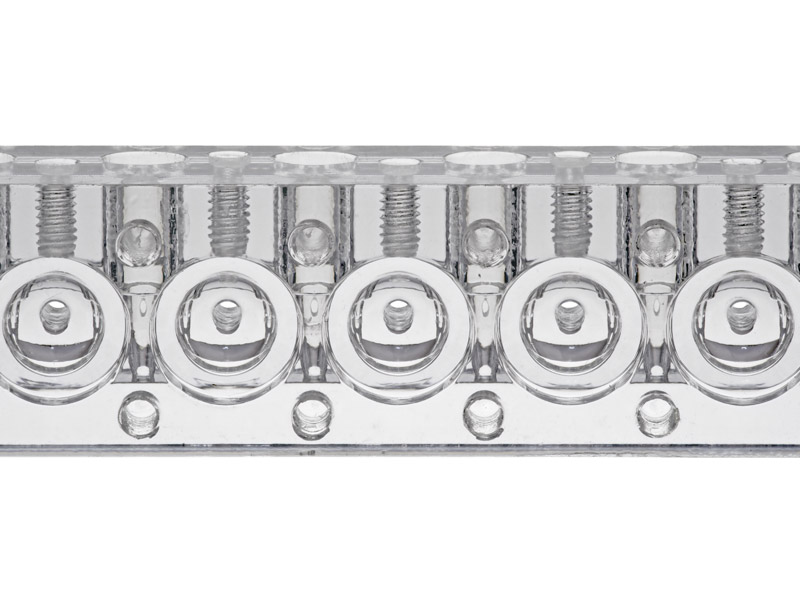

Our production mill department has the equipment, employees, software, and automation to make your parts quickly and consistently. We offer 3-axis, 4-axis and simultaneous 5-axis machining for production volume milled parts of any complexity or material. With more than 20 CNC mills and redundant capabilities, we are ready to tackle your next project.

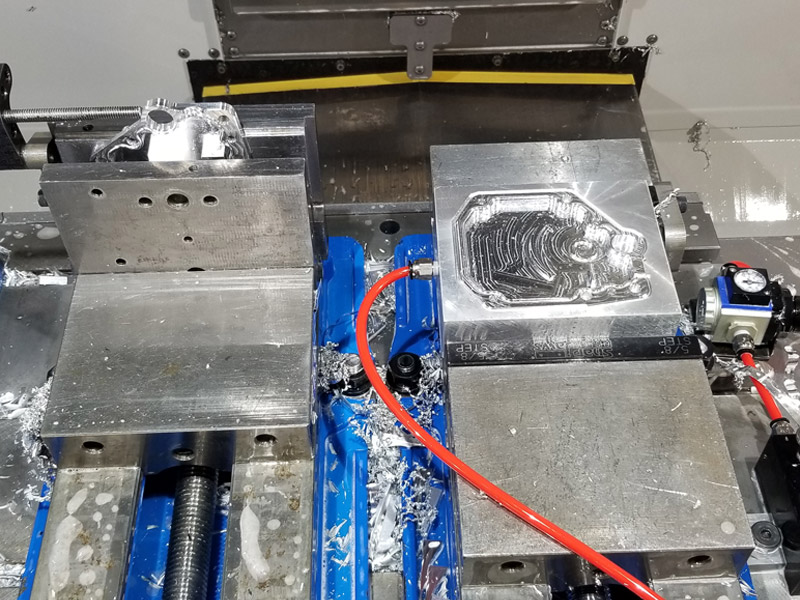

For mid to high volume 3-axis or 5-axis mill jobs, we have robotically loaded machining cells. This capability allows us to maintain consistent and extended production for jobs that require it. Similar to our mills, we have redundant automated cells for even higher volume or additional flexibility in our production schedule.

Our Experience

We purchased our first CNC mill in 1986 and have been pushing the limits ever since. With the addition of 5-axis machining in 2010 and robotic automation soon after, we greatly expanded our capabilities. Our experience machining complex prototype parts keeps us sharp and creative to tackle your most demanding production jobs efficiently. The addition of ISO9001:2015 and AS9011D certification shows our commitment to high standards of quality and customer service.

We document every job, by saving the programs, setup sheets, and digital pictures of each setup. Included in that information are any deburring and finishing notes. We also keep a tooling pack that contains any custom fixtures or special tools that are required for the job. We have integrated all of this into our shop management software, so all of the information is linked to the job in our ERP system. All this documentation allows us to quickly set up your job in the future, and helps us to guarantee consistent part quality from one run to the next.