If you’re looking for a reliable defense and aerospace machining partner, look no further than our AS9100 machine shop. Whether you need prototypes or high-volume productions, Wagner Machine has the right equipment, capabilities, and certifications to get the job done to even the most stringent specifications and requirements.

Wide Range of In-House Machining Capabilitie s

s

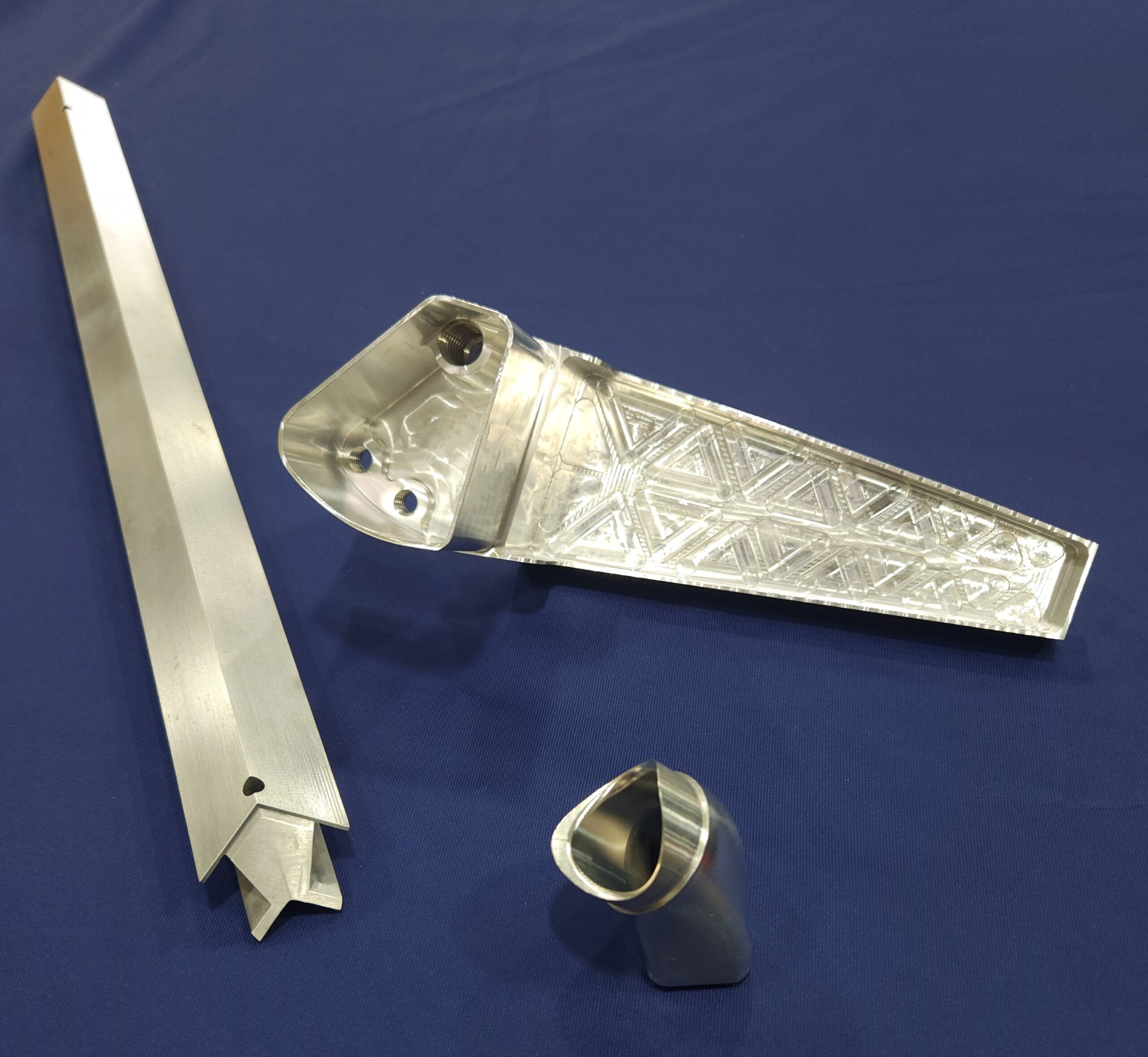

One of our biggest strengths and differentiators is the breadth of capabilities we offer in-house. Because we’re more than a standard milling and turning shop, the defense contractors we work with appreciate that they can send us complex packages of parts and consolidate vendors. Parts we commonly manufacture for defense contractors include electrical enclosures and optic and sensor components.

We recently quoted a defense project that involved turned parts, milled parts, wire EDM, and some outside processes for heat treating. Another recent defense RFQ that came our way involved 3- and 5-axis milling, turning, Swiss machining, and even waterjet cutting.

Typically, we only outsource operations related to heat treat or part finishing, such as electroless nickel, anodize, and specialty coatings. Even then, our shop project manages the entire process, so you don’t have to. Having one shop maintain full control of each project ensures exceptional quality and efficiency.

Experts at manufacturing complex machined parts

You may have noticed that we’ve mostly talked about our defense manufacturing experience up to this point. The truth is we haven’t had the opportunity to take on as many aerospace machining projects as we would like (mostly spaceflight projects so far), but we’re hoping to change that.

As a shop specializing in complex machined parts other shops deem “impossible” to manufacture, Wagner Machine is adept at achieving tight tolerances and intricate features using our advanced equipment and our team’s ingenuity. Our processes are optimized for smaller parts than many shops and that specialization leads to better efficiency and consistency. We would love to quote your 5-axis mill parts under a 10” cube or turned parts under 2.625” diameter.

Defense and Aerospace Machining Certifications

Wagner Machine is proud to have the necessary certifications defense and aerospace customers look for when selecting a precision machining partner.

AS9100

We maintain AS9100 certification in addition to ISO 9001:2015 certification. As you know, AS9100 is an aerospace-specific standard with additional quality management requirements that are critical for high-risk aerospace manufacturing.

NIST SP 800-171 and CMMC

In an increasingly digital world, it has become standard for defense and aerospace customers to ask suppliers how they handle cybersecurity. Wagner Machine has always prioritized cybersecurity. That is driving our push for NIST SP 800-171 and, eventually, CMMC 2.0 compliance.

Though CMMC 2.0 will not be a contractual requirement for defense contracts until the US Department of Defense completes rulemaking to implement the program, we are preparing for it already. CMMC Level 2 compliance is based heavily on the pre-established NIST SP 800-171 standard, which outlines “recommended security requirements for protecting the confidentiality of CUI when the information is resident in nonfederal systems and organizations.”

We aim to be fully NIST SP 800-171 compliant by October 2024, giving us the smoothest path to CMMC 2.0 compliance once the standard is finalized. Some of the security measures we have implemented and are working on include:

- Maintaining multiple layers of secure backup for customer data

- Encrypting all traffic

- Using specific cloud services that meet high standards for cybersecurity

For example, did you know that the popular Autodesk Fusion 360 CAM software isn’t ITAR, NIST SP 800-171, or CMMC 2.0 compliant? Although we love some features of this cloud-based software and it is included with other software licenses we have, our shop does not use it—not just for defense projects but for any projects. That’s how serious we are about cybersecurity and customer information.

A Reliable Partner for Defense and Aerospace Machining

Wagner Machine has everything it takes to be a reliable defense and aerospace machining partner: the right equipment, the capabilities, and the right certifications. Request a quote to work with us!